The need to automate workloads has become a reality

Previous situation of the client

Having implemented a telematics system in fleets of simple machinery in its fleet of 300 machines, the level of digitalization was low. Through machine fleet monitoring, the customer could basically see where the machines were and little else. It wasn’t using the service to launch automated events, capture machine hours, or automatically launch preventive maintenance overhauls or remote control of generator sets. Nor did it have a control panel where it could see the general status of the fleet. In this way, despite having a fleet management system, the level of digitalization and automation of all these repetitive tasks was below 5%.

digitalization was low. Through machine fleet monitoring, the customer could basically see where the machines were and little else. It wasn’t using the service to launch automated events, capture machine hours, or automatically launch preventive maintenance overhauls or remote control of generator sets. Nor did it have a control panel where it could see the general status of the fleet. In this way, despite having a fleet management system, the level of digitalization and automation of all these repetitive tasks was below 5%.

Areas for improvement detected through telematics in machinery fleets

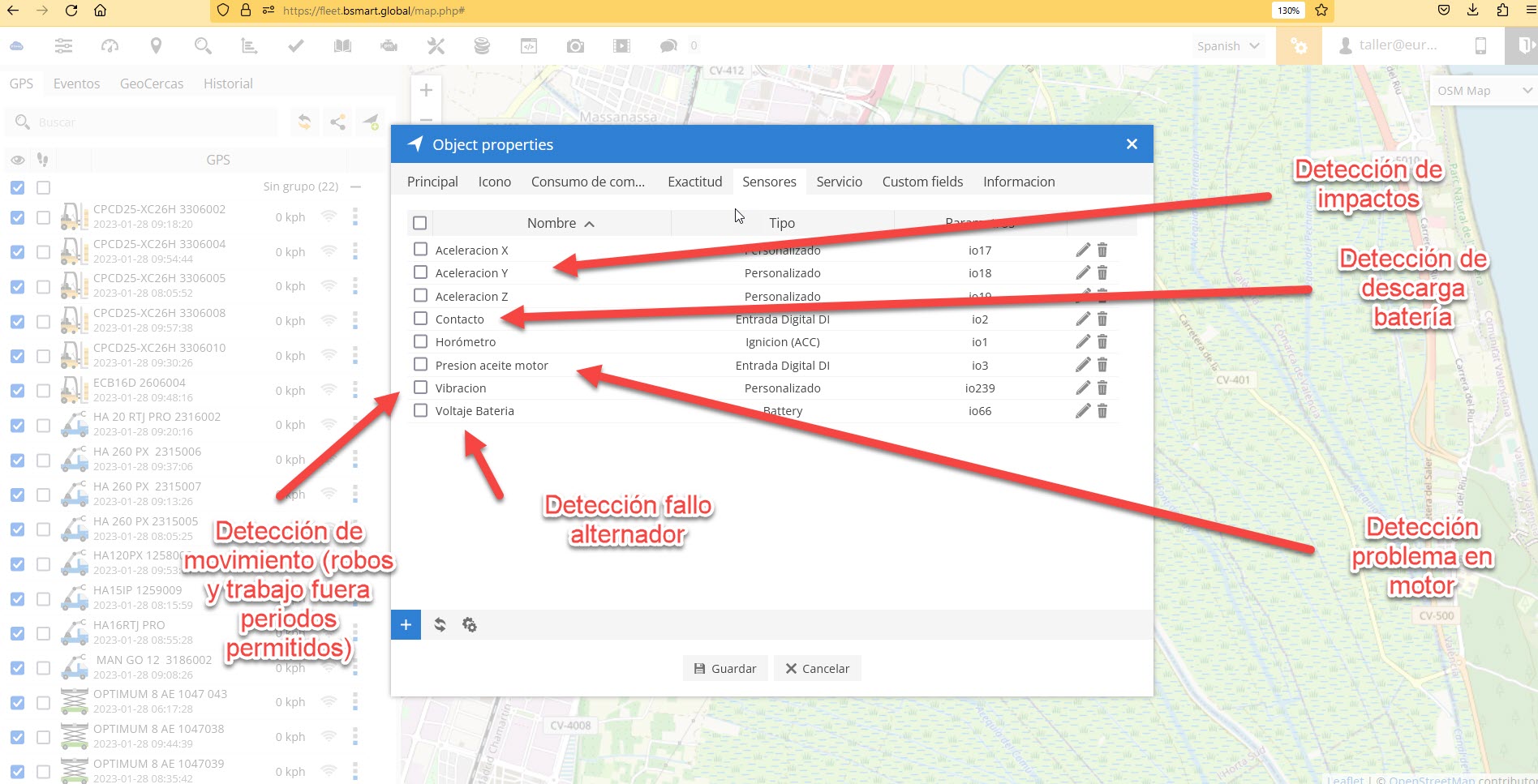

- Machine hours were collected manually, and because of this there were deviations and lack of control in preventive maintenance checks, especially if the machine was rented for long periods of time. This system also caused that in some cases more checks were made of the account, in addition the client did not have a control panel that showed the status of the fleet quickly.

- The fuel used by each machine and the refueling in diesel machines was controlled manually with the corresponding loss of time in repetitive tasks that did not add value.

- The control of where each of the machines was located (Preparation, prepared, workshop, en route to the customer, returning to central, etc.) was not automatic, therefore, time was lost in calls between office and workshop to locate these machines and know the status.

- The customer had no record of when the machine was leaving or arriving unless there was a telephone communication. Thus, the quality of customer service has been improved, sharing a temporary link automatically and with the real-time position of the machine once it leaves in the direction of the customer. In this way, the customer can know at all times the position of the machine without having to make calls.

- The rental management system was done through an Excel, which was cumbersome and slow. A quick and easy to use platform has been implemented that communicates with our fleet management system and maintains automatic control of where the machines are, at what stage (workshop, preparation, preparation, etc.) or in which customer. The same rental control system will in the future be able to provide information on which customers have rented, what machines, how many hours, when, how, where they have been, etc. All this Business Intelligence information can be used to extract information on the return on investment of each machine and, therefore, business performance.

Improvements for the immediate implementation of telematics in machinery fleets

By starting to work with our telematics platform in machinery fleets, and consequently achieving the digitalization of the fleet, the customer obtains:

- Capture of machine hours remotely,avoiding manual work of both the technician and the person who fed the maintenance software.

- Generation of automated preventive review notices, thus providing a more exhaustive control.

- Remote machine shutdown if necessary.

- Automated notices and reports about machines working outside the stipulated hours , for example, on weekends.

- Capture of the fuel level and refueling of the machines automatically. Information that travels digitally to the corresponding management software from the machinery fleet monitoring system.

- Warning and reports on machine inclination to avoid accidents and to be able to document in case of incident or accident.

- Notice of passage of the machine between different phases; machine in preparation, machine prepared, machine in the workshop, arrival at customer X, etc.

- Automated notification by mail with temporary link of departure and arrival of the machine to the client.

- Remote control of generator sets or any other machine.

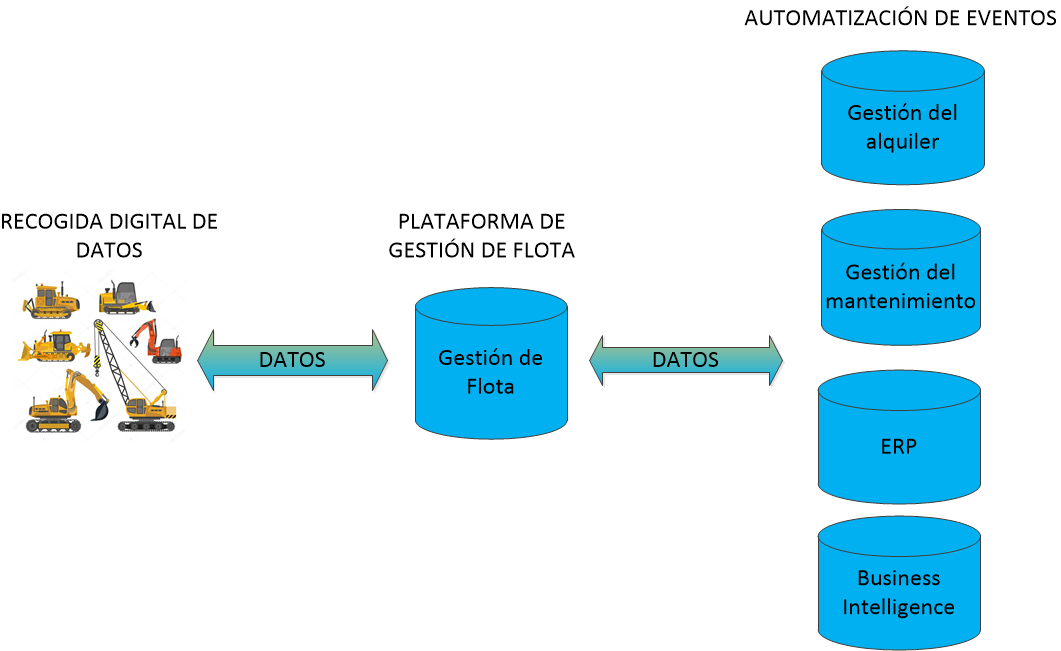

- Connection of the fleet management system with the different platforms that are part of the normal operation of the company to improve control and avoid manual tasks, as well as achieve the generation of value of the data collected.

Using 100% of the data generated by telematics in machine fleets to generate value

Using 100% of the data generated by telematics in machine fleets to generate value

Once telematics has been implemented in machinery fleets,  we have connected this platform with the rest of the platforms used by our client via API. In this way, 100% of the data generated by our fleet management platform is employees to generate value. The data collected from the machines is sent to the fleet management system, which in turn automatically feeds other systems such as rental management software or ERP. This allows automating and digitizing all those repetitive actions, such as Generation of invoices, automatically adding and attaching a report with the additional charges for weekend work, for example. In addition, this information can be easily shared with the different actors involved in rental management. We have, therefore, a fleet management system that, in addition to geo-locating the machines, represents a true digitalization of the business, using 100% of the data to generate value.

we have connected this platform with the rest of the platforms used by our client via API. In this way, 100% of the data generated by our fleet management platform is employees to generate value. The data collected from the machines is sent to the fleet management system, which in turn automatically feeds other systems such as rental management software or ERP. This allows automating and digitizing all those repetitive actions, such as Generation of invoices, automatically adding and attaching a report with the additional charges for weekend work, for example. In addition, this information can be easily shared with the different actors involved in rental management. We have, therefore, a fleet management system that, in addition to geo-locating the machines, represents a true digitalization of the business, using 100% of the data to generate value.

You can see here our last webinar in which we exposed each and every one of the aspects discussed here regarding the monitoring of machinery fleets and the remote control of generator sets.