Fleet Optimization and Cost Reduction with CAN BUS Technology

Success Story: Total Elimination of Breakdowns due to Clogging of the Particulate Filter in Diesel Machinery

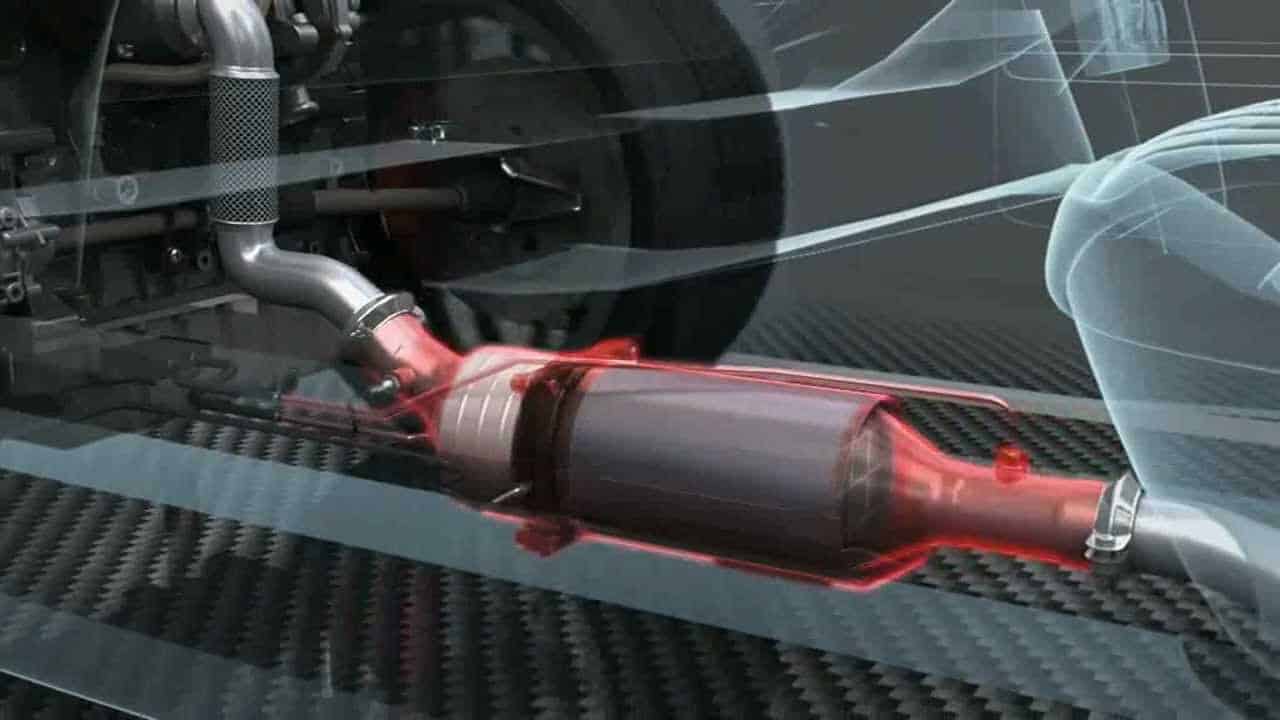

The particulate filter plays a crucial role in the exhaust system, retaining solid particles. When the temperature exceeds 400 ºC, a regeneration process begins, where the particles are eliminated by pyrolysis. However, if optimal conditions are not reached, the filter can become clogged, which has been a common challenge for machine rentals.

However, if optimal conditions are not reached, the filter can become clogged, which has been a common challenge for machine rentals.

The Client

Our client is a leading machinery rental company with a fleet of more than 400 machines, including loaders, excavators, generators and tractors, mostly diesel. With a fleet that is constantly being renewed, the problems associated with the particulate filter are intensifying.

The Problem

These machines require regular regeneration, but operators often ignore machine warnings due to the disruption involved. The result of ignoring these warnings is the clogging of the particulate filter, with a cost of between 3,000 and 10,000 Euros per cleaning or replacement. Our client was facing long downtime and high costs that they were not willing to take.

The Solution

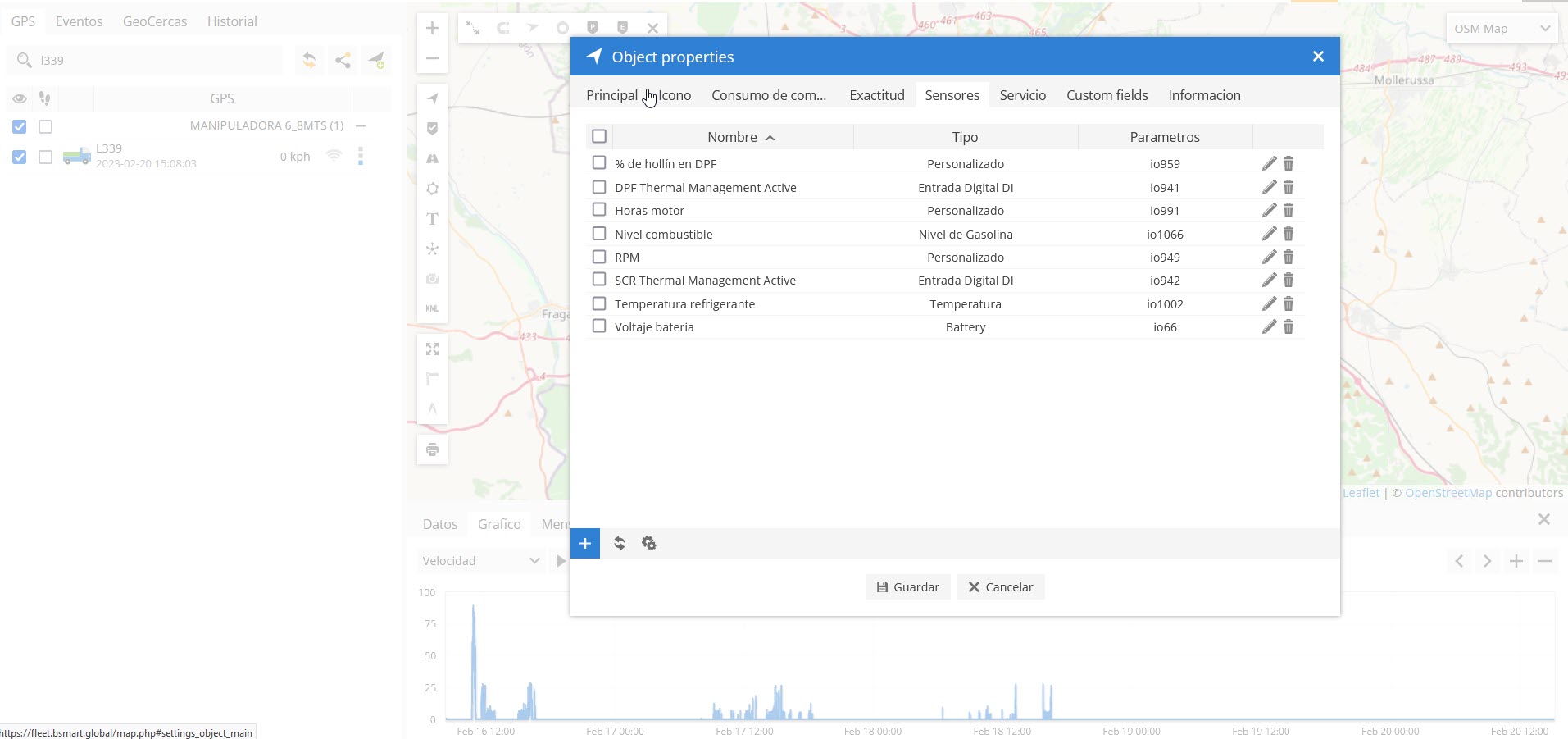

We implemented fleet digitalization, allowing our client to monitor in real time the status of the particulate filter in all their machines. In addition to the information on the DPF, we obtain other critical parameters for the constant monitoring of the machine, with notifications through different channels. This even makes it possible to stop or slow down the machine if necessary, avoiding costly breakdowns that, in most cases, customers are not willing to assume.

CEO Comment

“In our company we are committed to cutting-edge technology to provide innovative solutions to our customers. The implementation of CAN BUS technology has been a milestone that not only revolutionized our fleet management, but has also generated a significant economic and operational impact, as we have reduced the costs associated with clogging the particulate filter by 2,400 Euros/month.”

Workshop Leader’s Comment

“The introduction of CAN BUS technology has completely transformed our fleet. We have witnessed a 98% reduction in breakdowns related to particulate filter clogging, which has resulted in the elimination of 4 monthly field visits due to breakdowns due to clogging of particulate filters (approximate cost of 100 euros/visit) and a total clogging that translates into 2,000 monthly costs.”

To see the solution in action, watch the video here.

Request the list of machine makes and models from which we extract CAN BUS information, as well as the specific parameters.

This case study illustrates the transformative power of CAN BUS technology in fleet management. We pride ourselves on collaborating with visionary clients to revolutionize their operations.

If you have any questions or would like to explore how CAN BUS technology can benefit your business, please do not hesitate to contact us.

Download here the list of brand and model of machines from which we can extract the information of the CAN BUS, as well as the parameters that we extract.