New Features of Our Advanced Fleet Digitization Solution

Fleet digitization continues to advance thanks to technological innovations, and our solution has evolved to offer new fleet digitization functionalities to provide our customers with a more complete, secure, efficient and quickly adaptable experience. quickly adaptable experience for our customers.. It should be noted that our solution is compatible with any machineregardless of its age, make or model, ensuring a versatile and accessible deployment in a wide variety of technological environments.

customers with a more complete, secure, efficient and quickly adaptable experience. quickly adaptable experience for our customers.. It should be noted that our solution is compatible with any machineregardless of its age, make or model, ensuring a versatile and accessible deployment in a wide variety of technological environments.

With the addition of advanced functionalities, our system has been designed to optimize performance, improve safety and facilitate control over all aspects of fleet operation. Here are the main new features of this update.

Real Time Notifications via WhatsApp, Telegram Slack, and automatic phone call thanks to the new fleet digitization functionalities

Our platform now allows for customized notifications to be sent via WhatsApp, Telegram, Slack and automated phone call, ensuring that critical messages reach the right teams quickly and directly. This capability is ideal for informing fleet managers about maintenance alerts, emergency conditions or any other situation that requires immediate attention.

Advanced Vehicle/Machine Condition Monitoring and Safety

To protect assets and optimize their performance, we’ve incorporated advanced real-time monitoring features including:

– Detection of DPF clogging, lack of diesel, excess temperature, pressure and other critical indicators. The system can take automatic actions, such as inhibiting machine operation in case of risk.

– Remote sensing of inclinometer, overweight and tilt angle. Ideal for operations on uneven terrain, this feature ensures safety control and avoids potential incidents.

– Generator load management. Detects overload, underload and load unbalance in generators, ensuring their safe and efficient operation.

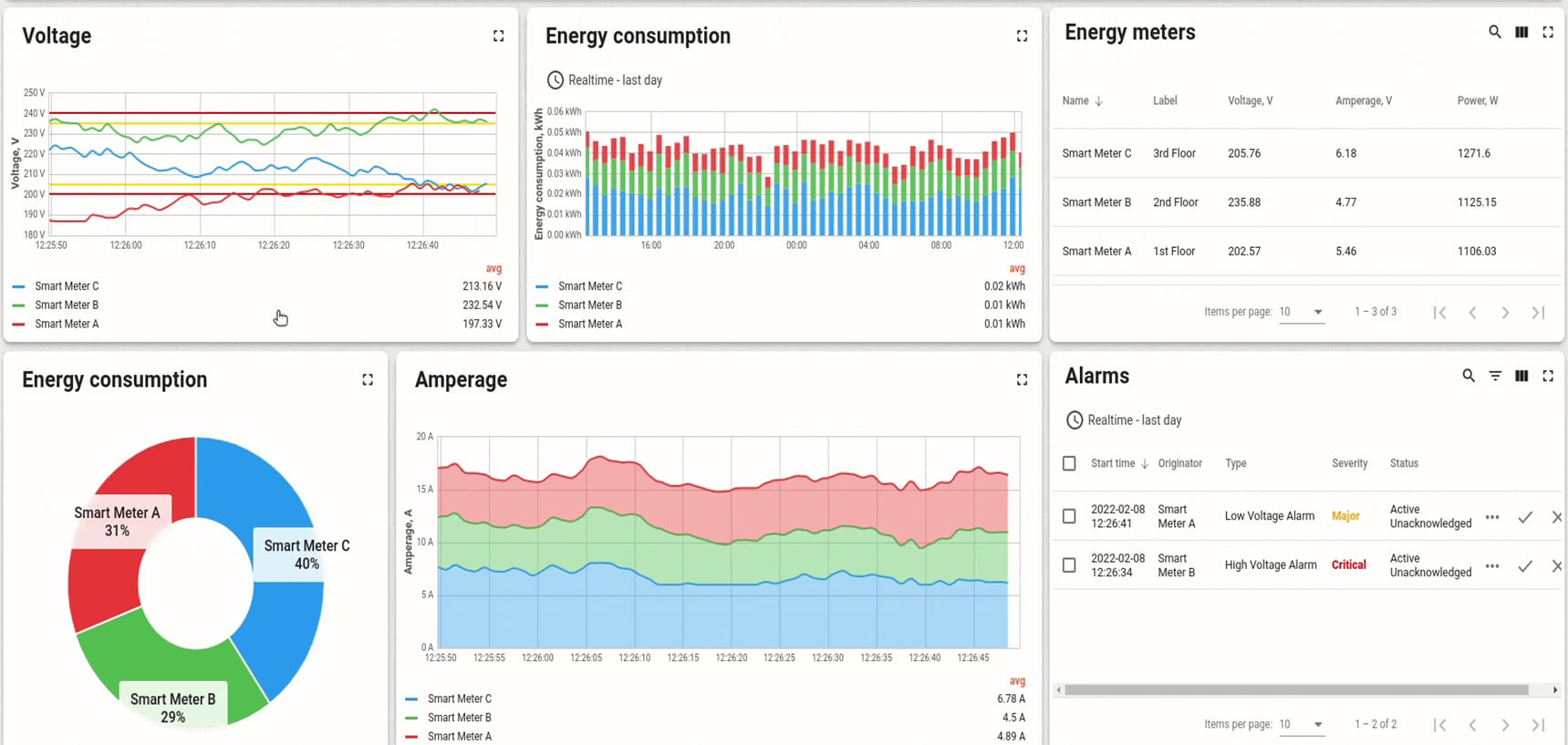

Total monitoring and control of power generators

Electricity Consumption and Production

- Phase Compensation (AMP): Graphical display of the phase balance by means of toroids.

- Energy Production (kW): Calculation based on measured current.

- Working Regime (%): Calculation of the load percentage in relation to the total production capacity – Average Fuel Consumption at 50% of Capacity: Data obtained from the CAN BUS or calculated by means of a gauging device.

Level Monitoring

- Fuel level (0-1): Information obtained from CAN BUS or digital input.

- Adblue level (0-1): Measurement from CAN BUS or digital input.

- Particulate FilterClogging(%): Information captured from CAN BUS.

- Average consumption at 50% of capacity: Automatic calculation.

- Oil Pressure: Data provided by the CAN BUS.

Alarm Management

- Particulate Filter > 80%: Integrated in the platform.

- Interrupted Regeneration: Detected from the CAN BUS.

- Working Regime > 70%: Monitoring based on RPM or current calculation.

- Fuel/Adblue < 15%: Alarms configured from CAN BUS or corresponding sensors.

- Uncompensated Phases: Detection by monitoring the current balance (toroids).

- Low Load: Identification from the captured current.

- Adblue temperature: Registration from CAN BUS or by additional sensor.

- Oil Leakage: Monitoring of sustained pressure drops from the CAN BUS.

- Other Alarms Present (Y/N): Signal capture from CAN BUS or additional sensors.

Possibility to stop the machine

A control system is implemented that allows manual or automatic machine shutdown in the event that an anomaly is detected or in emergency situations. This is achieved through a secure user interface or through a safety protocol integrated into the machine control system.

Data analytics layer

An advanced data analytics layer has been incorporated that will collect, process and analyze relevant machine information, including operational, historical, performance and failure data. This layer will use artificial intelligence and machine learning algorithms to provide predictions on preventive maintenance, machine efficiency and other metrics important to the operation.

Automatic machine type detection

The system will be able to automatically identify the type of machine using sensors and standard communication protocols (such as CAN Bus). This includes electric machines with 48V and 80V traction batteries, diesel machines and diesel with CAN system. Detection will be done by reading key parameters such as voltage, fuel type, and electrical or engine characteristics, ensuring that the appropriate procedures are applied for each machine type.

Sending commands through the CAN BUS

Sending commands through the CAN BUS is an advanced functionality that allows direct interaction with the electronic systems of machines or vehicles. This capability not only facilitates remote management, but also extends control over various operations and parameters in real time.

Main Command Sending Applications:

- Remote Operations Control:

- Activation or deactivation of specific systems (e.g., engine on/off).

- Management of auxiliary devices such as lights, pumps, or hydraulic systems.

- Configuration and Parameter Setting:

- Adjustment of speed limits, working speed, or production capacity.

- Modification of alert thresholds, such as oil pressure or fuel levels.

- Active Regeneration Management:

- Initiation or interruption of regeneration processes in particulate filter systems (DPF).

- Confirmation of the status of ongoing regenerations.

- Diagnostics and Preventive Maintenance:

- Request for additional data to assess the status of the systems.

- Resetting alarms or error codes after troubleshooting.

- Optimization of Consumption and Production:

- Demand-driven adjustment of motor or equipment performance.

- Configuration of operating modes, such as “eco” or “maximum performance”.

Traction Battery Management and Control

For the fleet using traction batteries, we have introduced remote monitoring of charge and discharge cycles, as well as remote monitoring of the water level in the electrolyte and remote element failure detection. This monitoring makes it possible to foresee problems before they occur, ensuring that the batteries always operate in optimal conditions and prolonging their service life.

Dynamic Groups for Fault Management and automatic machine segmentation based on certain conditions

This functionality makes it easy to detect and group faults based on their characteristics and priorities. In this way, maintenance teams can focus their efforts on urgent repairs, while the rest of the incidents are effectively scheduled.

It also allows us to know quickly which machines meet certain conditions, for example:

- Qué máquinas han trabajado el fin de semana

- Qué máquinas están pendientes de revisión

- Which machines have worked for more than a certain number of hours

- Qué máquinas se han sufrido una determinada avería en un determinado periodo de tiempo.

- How many and which traction batteries are missing water in the elements or have been charged more than once a day (lead-acid batteries)

- What, and how many devices are incorrectly installed and which ones do not have GPS signal, perhaps also due to incorrect installation

Theft Prevention with automatically created GeoBarriers

Through geofences, when the machine is rented, our platform allows us to detect theft attempts or unauthorized movements. If a vehicle leaves a certain area without authorization, the system will send an automatic alert, allowing a quick response to possible theft attempts.

Automatic Stock Control between Delegations

Inventory optimization is key to operability and can now be managed automatically between delegations, allowing better control of the machinery fleet, as well as the timely distribution of resources according to needs.

Detection of Delegation Arrivals and Departures with KPI Capture

With our new real-time monitoring technology, the arrival or departure of each vehicle in a delegation can be automatically detected and metrics such as diesel level or any other relevant KPIs can be captured. This allows for precise control of daily operation and facilitates the analysis of operational efficiency.

Data Analytics with Predictive Maintenance and Automatic Anomaly Detection

Advanced analytics enables  predictive maintenance and detects anomalies before they become serious problems. Thanks to Machine Learning algorithms, our system anticipates maintenance needs, enabling proactive scheduling and reducing the risk of unexpected breakdowns.

predictive maintenance and detects anomalies before they become serious problems. Thanks to Machine Learning algorithms, our system anticipates maintenance needs, enabling proactive scheduling and reducing the risk of unexpected breakdowns.

Real-Time Location (LBS) thanks to new fleet digitization functionalities

Con la función de Localización Basada en Servicios (LBS), la plataforma ofrece información detallada sobre la ubicación exacta de cada vehículo, no solo a través de GPS sino también utilizando la tecnología LBS, permitiendo una supervisión más eficiente cuando la señal GPS no está presente (parkings, túneles, etc)

Inclusion of Documents and Photographs in Maintenance and Fault Recording

It is now possible to add documents and photos to preventive maintenance records and fault history. This feature makes it easy to track each incident, provides visual context, and helps improve diagnostics for future inspections.

Aggressive Driving Monitoring and Speeding Control

To increase road safety and reduce maintenance costs, we have included aggressive driving monitoring using the RAG index and speeding control based on the maximum speed allowed on each road. This functionality promotes safe driving practices, helping to reduce accidents and optimize fuel consumption.

Access to Documentation and External Links

To facilitate the operability of fleet equipment, the platform allows direct access to documents and external links. This is ideal for consulting manuals, operating instructions and any other necessary resources.

Holistic and Personalized Approach

Our digitization solution can incorporate data sources that don’t necessarily belong to the fleet. This provides a holistic approach, allowing third-party information to be managed, such as data from external suppliers or resources that interact with the fleet operation. The diesel fuel tanks present in many of the delegations and used to refuel the machines.

Segmented and Prioritized Alarms

The system allows you to configure segmented and priority alarms, providing greater control over notifications. With this functionality, administrators can receive alerts organized according to their criticality, thus avoiding information overload and achieving more effective responses to urgent situations.

Incorporation of Video Cameras in the Dashboard

In some cases, our customers incorporate cameras into their vehicles or machinery. To offer a higher level of visibility and control, the platform now allows the integration of video cameras into the main Dashboard. This facilitates real-time visual monitoring of the conditions and environment of machinery and vehicles, providing a complete view of the operating and safety status.

Diagnostic Code Capture

Our solution now offers CAN BUS diagnostic code capture functionality. With automatic diagnostic code capture, it is easier and faster to identify and resolve technical problems.

CAN J1939, CAN OPEN and MODBUS reading

Many machines operate under the J1939 standard; however, others use less common standards, such as CANopen or MODBUS. Our solution is fully compatible with these protocols, allowing to read and process data from each of them efficiently.

Detection of machine work on weekends even on machines without batteries

Thanks to our new energy-saving technology and the use of advanced hardware, the B’Smart solution can monitor the work of any machine on the weekend.

Automatic detection of incorrectly installed devices thanks to new fleet scanning features

Automatic detection of incorrectly installed devices is a key feature to ensure the optimal performance of our fleet digitization solution. This functionality allows the platform to proactively identify any device that is not correctly installed, which is crucial to maintain the integrity and operational efficiency of the fleet.

When an incorrectly installed device is detected, the platform will immediately generate an alarm, alerting operators to the problem.

This early warning is vital to:

- Minimize operational risks: By detecting improperly installed devices early, you prevent problems from escalating, which could result in significant disruptions to fleet operations.

- Ensure optimal performance: The correct installation of technological devices is essential to maximize the efficiency and effectiveness of operations, ensuring that all components work in harmony.

- Facilitate quick corrective actions: With real-time alerts, maintenance teams can take immediate action to resolve issues, thereby optimizing downtime and reducing costs.

This feature not only improves fleet reliability, but also strengthens investment in scanning technology, ensuring that each device is aligned with expected performance standards.

Here is an extended version with more details about the functionality:

Remote Logging of CAN BUS PGNs: Increased Efficiency and Operational Savings

It is now possible to capture CAN BUS data directly with the devices used for fleet digitalization, which represents a key advance in the optimization of machinery and vehicle management. This functionality allows the remote collection of information without the need to move personnel to the site, which translates into significant savings in time, operating costs and resources.

Key Benefits:

✅ Remote CAN BUS PGN logging – Devices collect data in real time without the need for physical connection in the field. ✅ Remote Configuration of Parameters – It is possible to identify and adjust the PGN’s of each machine without any on-site intervention. ✅ Resource Optimization – Sending technicians to the site for configuration tasks is avoided, reducing costs and downtime. ✅ Automation and Systematization – Data capture and device configuration is done in a structured way, reducing errors and improving operational efficiency. ✅ Facilitates Reverse Engineering – By accessing CAN BUS data remotely, analysis and identification of unknown or machine-specific parameters is streamlined, accelerating integration with different models and manufacturers. Thanks to this new capability, companies can more efficiently manage the configuration and analysis of their machines without interruptions or unnecessary travel, enabling more agile and accurate digitization.

These new functionalities represent a significant leap in fleet management and facilitate decision-making based on real-time data. Our solution focuses on providing a complete, efficient and personalized vision for each client, adapting to the specific needs of each operation.