Revolutionizing Generator Management: B’Smart Fleet Digitization Solution Enhances Data Capture and Remote Command Capabilities

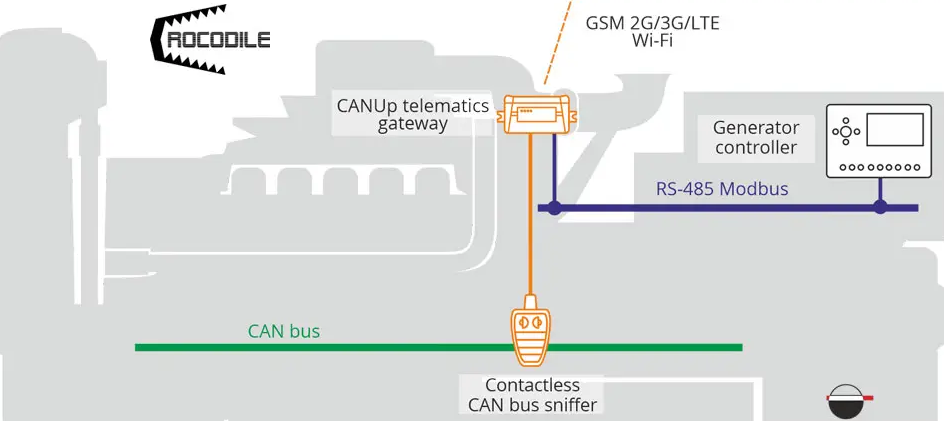

In today’s interconnected world, the demand for efficient, data-driven machine management solutions has never been greater. We are pleased to announce a revolutionary advancement in our fleet digitization solution: the ability to capture data directly from electric generator control units and monitor generators of any make or model, along with the ability to send remote commands via CAN Bus, CAN open, RS485, MODBUS and RS232. Generator monitoring directly from the ECU using RS485, MODBUS, CAN BUS and any other existing data bus redefines generator fleet management, offering unparalleled efficiency, cost savings and unprecedented operational control.

Monitoring generators directly ECU’sin Frontiers

One of the main challenges in generator management is the diversity of makes and models in fleets, each with unique control units and monitoring requirements. Our enhanced solution eliminates this complexity with universal compatibility across multiple communication protocols, including RAW CAN BUS, J1939, CAN open, RS485, MODBUS and RS232.

Regardless of make or model, our system integrates directly with the generator control units, capturing critical data such as:

- Operational Metrics: Engine hours, fuel levels and load capacity.

- Performance Indicators: Voltage, current, frequency and temperature.

- Alerts and Diagnostics: Fault codes, maintenance schedules and performance anomalies.

This capability allows fleet managers to centralize generator data on a single platform, providing real-time visibility into equipment health and performance.

Remote Command Capability Through Any DATA BUS

Our solution goes beyond monitoring by introducing advanced operational control through remote command functionalities. Leveraging the DATA BUS communication protocol, users can send precise commands to the generators, enabling functions such as:

- Calibration and Configuration: Adjust settings or recalibrate equipment remotely to optimize its performance.

- Troubleshooting: Address errors and reboot systems without requiring on-site intervention.

- Energy Optimization: Adapt generator output to match varying load demands in real time.

This remote access drastically reduces the need for technicians to travel to remote or hard-to-reach locations. By minimizing site visits, companies save on travel costs, reduce downtime and reduce their environmental footprint.

Real-World Impact of Generator Monitoring directly from the ECU

This innovation is not just a technological milestone, but a transformative operational tool. Imagine a generator located hundreds of miles away that experiences a failure. Traditionally, resolving the problem would require a technician to travel to the site, identify the problem and implement a solution, often resulting in significant downtime.

With our solution, you can now diagnose the fault remotely in minutes and issue corrective commands via DATA BUS. The result? Faster problem resolution, uninterrupted operations and significant savings in time and resources.

Commitment to Universal Efficiency

At the heart of this advancement is our commitment to universal applicability and ease of use. Our platform integrates seamlessly into existing fleet management systems, ensuring adoption without costly changes or operational disruptions. In addition, installation takes less than 15 minutes, minimizing downtime and enabling rapid deployment.

Designed to be easy to use, the system allows operators to manage complex operations through intuitive controls and interfaces.

Looking to the Future

This new capability represents a significant advance in generator fleet management. By combining universal compatibility, real-time monitoring and remote command functionality, we are empowering companies to achieve unprecedented levels of efficiency and control.

As industries continue to embrace digital transformation, we remain dedicated to driving innovation to meet the evolving needs of our customers. Whether managing a fleet of five generators or 5,000, our solution equips you to meet today’s challenges and prepare for tomorrow’s opportunities.

For more information on how our fleet digitization solution for generator monitoring directly through the ECU, please contact us.onitoring of generators directly through the ECU can transform your generator management operations, contact us today. Together, let’s build a future where efficiency has no limits.