Many users wonder how to maximize the life of batteries for electric machines. Optimizing the battery is essential to be able to extend the life of it, and therefore, to be able to justify the investment made in the acquisition of the forklift, whether we have bought it new or if we have acquired it in the second-hand market. The battery is the most expensive part of the truck, since it accounts for 30% of its price. Breakdowns in the power system are expensive to repair, so it is worth following some tips to enjoy all the benefits of the truck.

BATTERY CHARGING

The battery is the heart of the electric models and we will take care of it according to its importance. First of all, we must keep in mind the specific advice of the manufacturer, which in some cases will be very useful to take concrete actions, but most batteries for forklifts appreciate very similar care and good use during work.

WORK BASED ON BATTERY CHARGE

Although the truck is a tool that we use for a specific service and our comfort, we must adapt our work in relation to the battery charge. Why? Mainly, to avoid unnecessary stops at work. In this way we will also reduce the possible accidents due to hasty maneuvers when we have little battery left: in short, better to plan than to do things quickly and badly.

LESS THAN 20% OF THE BATTERY IS THE CRITICAL POINT

Yes, critical. If the battery of a forklift is completely discharged some components will suffer significant damage and the engine may fail suddenly. In addition, at these load levels we cannot rely on the control of the forklift, because the hydraulic system and, especially, the traction do not work efficiently. Forget it, never hurry. Think that a discharged battery will have to be recharged for eight hours, so say goodbye to your workday for that day. Working under low electric load limits the performance of the vehicle and can put the safety of the operator at risk. It is estimated that a full charge cycle of a battery is 8 hours, it uses anintelligent fleet management system to know and control the charge cycles, and even stop the machine automatically when the battery is below the desired threshold.

DO NOT CHARGE THE BATTERY MORE THAN ONCE A DAY

To say that constantly recharging the battery causes premature aging seems like a no-brainer, but many workers abuse the loads. Install an intelligent fleet management system that lets you know how many charge and discharge cycles are occurring and extends battery life.

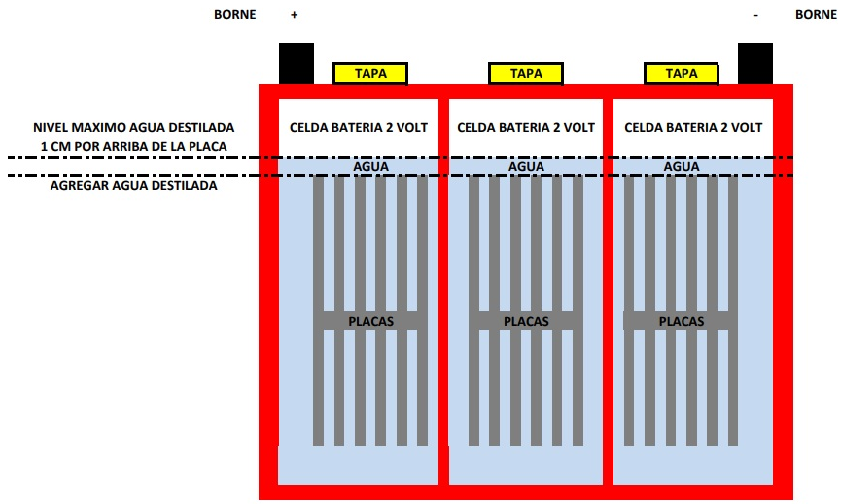

ELECTROLYTE LEVEL

The batteries of the trucks are  composed of a series of independent vessels or ducts, but connected to each other. If one of these vessels is defective, electricity will not flow properly. When we connect the battery to a transformer, we give way to a thermal process in which the electrolyte raises its temperature until it reaches boiling. In this process, some things will occur, such as the change of electric charge of the electrolyte, the evaporation and emission of flammable gases, etc.

composed of a series of independent vessels or ducts, but connected to each other. If one of these vessels is defective, electricity will not flow properly. When we connect the battery to a transformer, we give way to a thermal process in which the electrolyte raises its temperature until it reaches boiling. In this process, some things will occur, such as the change of electric charge of the electrolyte, the evaporation and emission of flammable gases, etc.

Therefore, it is necessary to check the level of the electrolyte, especially in summer, due to greater evaporation. The water level of the electrolyte of the entire fleet can also be known in real time and remotely through a good intelligent fleet management system,which will allow us at all times to know what is happening and even stop the machine automatically if this level is not correct or if the water falls to the chest, which will produce a corrosion of it.

SOME SPECIAL CARE

The top of the battery should always be clean and dry. To do this, we will pass a cloth moistened in water, pressurized air, a brush, etc. If we find spilled electrolyte, we can use a solution of water and 10% sodium bicarbonate, applying it with a brush, and then washing with water. It is important to check that, after cleaning, the holes in the plugs are not clogged. Connections should be protected with neutral petroleum jelly.

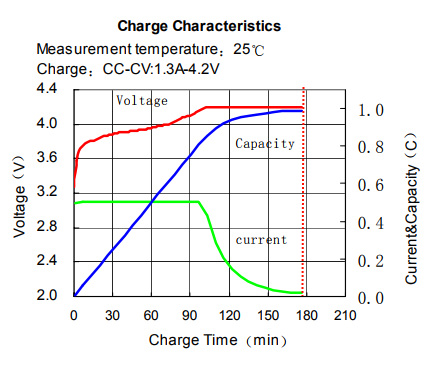

THE DANGER OF FAST CHARGING CYCLES

Sometimes we have seen some  professionals opt for fast recharge cycles. While it is true that stop times decrease, the counterpart is that a lot of heat is generated, which can reduce the life of the batteries by up to 10%,especially if they are lead. With lithium and nickel batteries, the same thing happens although in a less pronounced way.

professionals opt for fast recharge cycles. While it is true that stop times decrease, the counterpart is that a lot of heat is generated, which can reduce the life of the batteries by up to 10%,especially if they are lead. With lithium and nickel batteries, the same thing happens although in a less pronounced way.

In both cases, and having the correct intelligent fleet management system, we can know the temperature history of the battery and reduce or mitigate this risk.

OTHER TIPS

If in a review we see that white crystals have appeared in  the battery area, we must immediately contact the technical service to prevent sulfation. This is a problem that affects the use and autonomy of the battery.

the battery area, we must immediately contact the technical service to prevent sulfation. This is a problem that affects the use and autonomy of the battery.

Finally, it is convenient that before charging the battery of the forklift we check what the status of the plug and connector is.

FEATURES OF CHARGERS AND BATTERIES ON THE MARKET AND OTHER PRODUCTS

CHARGERS

Among the chargers that we can choose for our truck, are the automatic and the conventional.

High-frequency autoloaders have easy handling, high quality and performance. When the charger is connected to the battery, it provides the ideal recharge, whatever the discharge condition of the battery. They usually provide a recharge current contrary or reciprocal to the voltage of the battery. In this way, the charger will provide high current when the battery has low voltages and a low current if the battery contains high voltages.

The so-called conventional chargers can be used in each application, as they offer a high range and variety. Either for traction batteries, starter, semi-traction, etc. They provide excellent value for money.